Tushaco Pumps

Tushaco Pumps

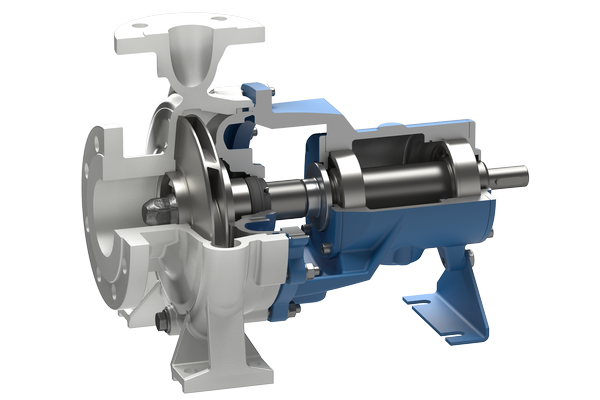

Centrifugal Pumps

In radial centrifugal pumps, the fluid is delivered and the pressure increase is brought about in a rotating impeller with vanes. This impeller is driven by a drive motor via a shaft and transfers mechanical energy to the pumped fluid continuously flowing through the impeller. The liquid enters the impeller axially and is accelerated from the inside to the outside by the effect of centrifugal force. This results in a transfer of energy into pressure and velocity energy. At the outlet of the impeller, the liquid enters the volute casing where the flow velocity is again slightly reduced. As a result of further energy conversion, the pressure increases. Through the volute, the liquid is directed to the pump outlet.

Crescent Internal Gear

CIG (Crescent Internal Gear) pumps are produced primarily for fluid power applications and aircraft fuel test stands.

They are available in multiple stages for very high pressure or moderate pressure on very low viscosity fuels. Pumps are also available in double pump configurations which share a common inlet port but deliver two independent flows for supporting multiple machine functions.

The patented tooth profile of CIG pumps avoids trapping fluid. The result is a very low pulsation, extremely quiet high efficiency pump.

Single pumps are available in 54 different models and double pumps in over 1300 different combinations.

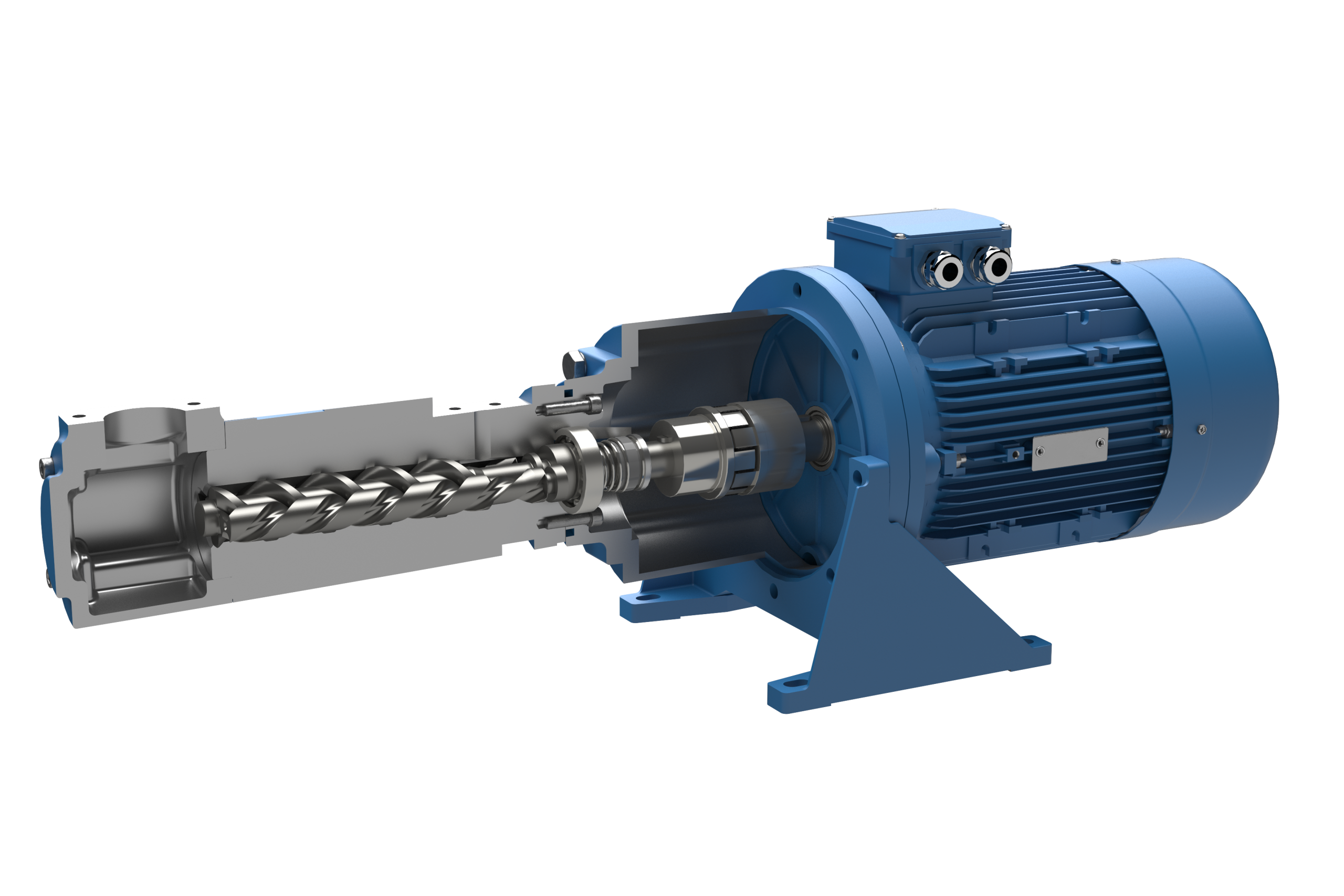

Three-Screw Pumps

Screw-Pumps with three spindles, known as Three-Screw pumps, are part of the screw-pump family. They are characterized by high power density and great versatility thanks to their compact design. Thanks to the unique design with three intermeshing screws, they provide extremely efficient and uniform flow, resulting in impressive overall efficiency.

Screw-Pumps in general are true all-rounders. They can handle a wide range of fluids, viscosities (0.3 to 100,000 cSt), gas contents (up to 100 %) and abrasive media. They are characterized by excellent controllability with nearly constant efficiency over a very wide operating range (flow and pressure). As with volumetric displacement pumps, the flow rate is determined by speed and is not dependent on pressure, density or viscosity.

Twin-Screw Pumps

Twin-screw pumps (TSP) are heavy-duty, general-purpose pumps used in a wide variety of applications. Excellent flow control with the highest efficiency over a wide operating range for almost all types of fluids and fluid viscosities make these pumps unique. TSPs are self-priming pumps with excellent suction lift, smooth operation and very low NPSH requirements. The ability to clean in place (CIP) is not the only way to simplify processes, improve product quality and reduce operating costs.

A unique feature of TSPs is their ability to provide constant flow regardless of system pressure requirements. Pump flow rate is a function of pump speed – the pump pressure is a function of the hydraulic system response. Whatever pressure the system requires, the pump will support any pressure up to its rated pressure at any speed. Furthermore, the pump only needs the energy related to actual flow and actual pressure requirements of the hydraulic system.

Precision Gear Pumps

At Zenith, we believe in providing our customers with precision and consistency by designing and tailoring your metering pump and pump systems to process most applications.

Since 1920, Zenith precision gear metering pumps and systems have provided accurate, reliable and pulse-free metering performance over a broad range of applications like dosing, filling, injection, coating, extruding, and many more! Zenith pumps are designed to handle all kinds of application fluids, be it abrasive‚ corrosive‚ hot‚ cold‚ viscous‚ toxic, or shear sensitive.

As part of the CIRCOR family of brands, Zenith combines exceptional engineering with a focused attention to your needs-from cost to overall product appeal-attention that’s always backed by an experienced support team.

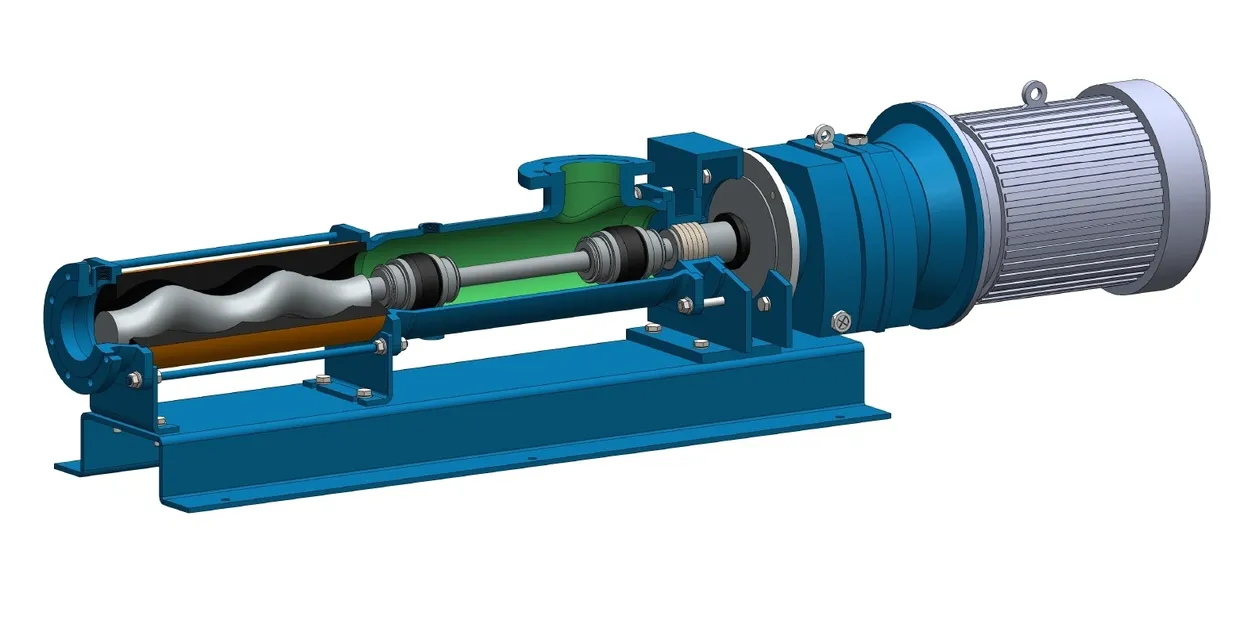

Progressing Cavity Pumps

Progressing Cavity Pumps (PCP) are high-quality, reliable and efficient pumping solutions designed for a wide range of applications. Known for their rugged construction and precise technology, these pumps are ideal for industries such as wastewater treatment, pulp and paper, chemical processing, food and beverage, and more.

With their unique design, these pumps provide continuous flow with low pulsation, unaffected by pressure and viscosity fluctuations. They are also self-priming and capable of handling high solids and abrasive materials. Easy to maintain and available in a variety of sizes and configurations, these pumps can be tailored to meet specific requirements.