Sam Turbo

Sam Turbo

Product Facts :

- Pump Size : DN50mm to 350mm.

- capacity : upto 2800m3/hr.

- Head : upto 70m

Features:

Twin Casing | Heavy Duty & Single Stage | Outer Casing in CI | Carbon Steel | Inner Casing in Ni – Hard / Hi – Chrome To Take Inner Wear.

Applications:

Ash Slurry in thermal power stations | Aluminium Industries – Hydrate, Seed, Bauxite and red mud slurries | Lime mud Slurry, Milk Of Lime, Liquor upto 50% Solids | Coal Slurries & Floatation Tailings | Iron Ore in Benefication Plants | Sand Water Mixtures | Liquid of abrasive and coarse grained solids.

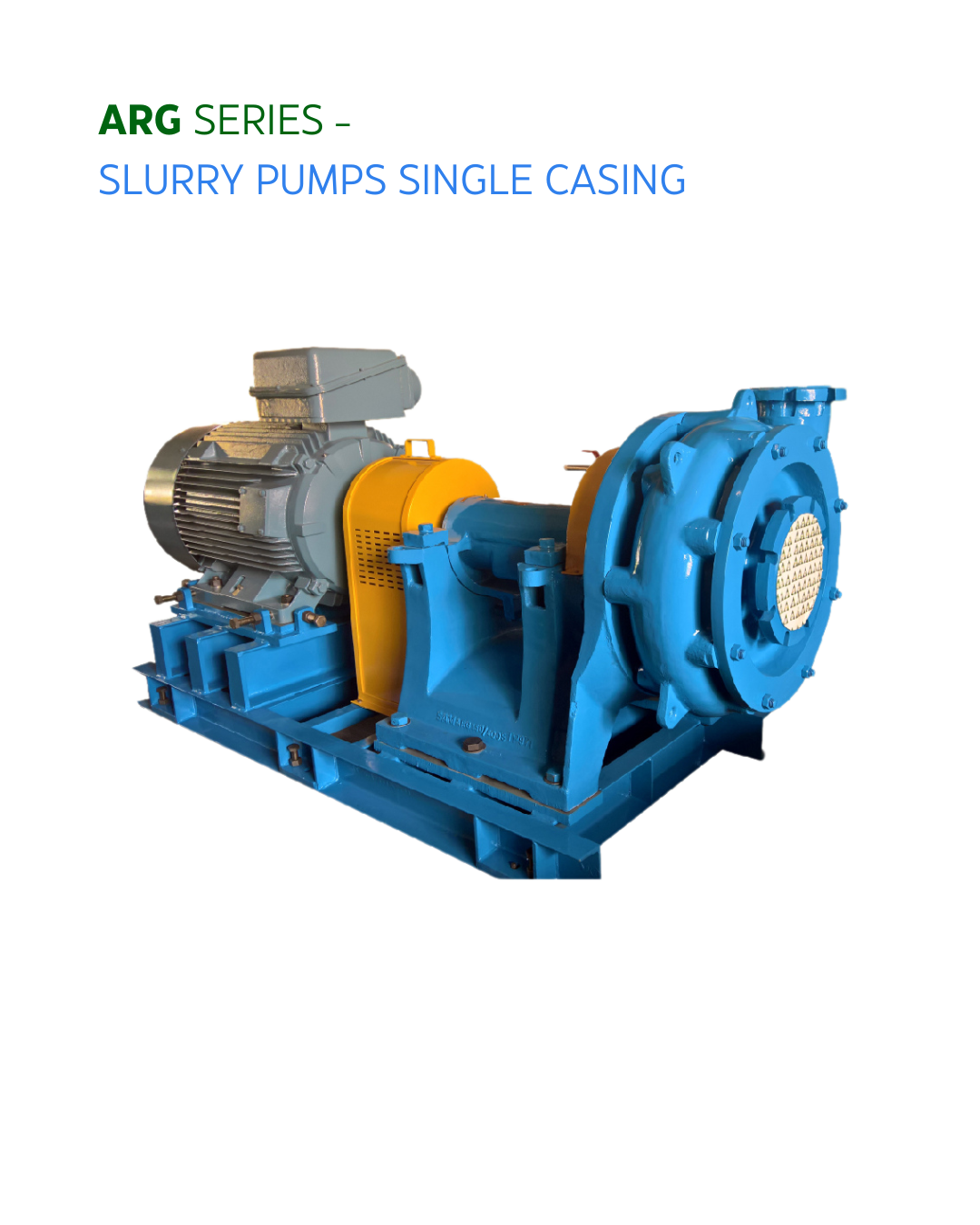

Product Facts :

- Pump Size : DN50mm to 400mm.

- capacity : upto 2000m3/hr.

- Head : upto 60m

Features:

Heavy Duty | Single Casing | Single Stage | Hi – Chrome / Ni – Hard – Casing to take entire wear.

Applications:

Ash Slurry in thermal power stations | Aluminium Industries – Hydrate, Seed, Bauxite and red mud slurries | Lime mud Slurry, Milk Of Lime, Liquor upto 50% Solids | Coal Slurries & Floatation Tailings | Iron Ore in Benefication Plants | Sand Water Mixtures | Liquid of abrasive and coarse grained solids.

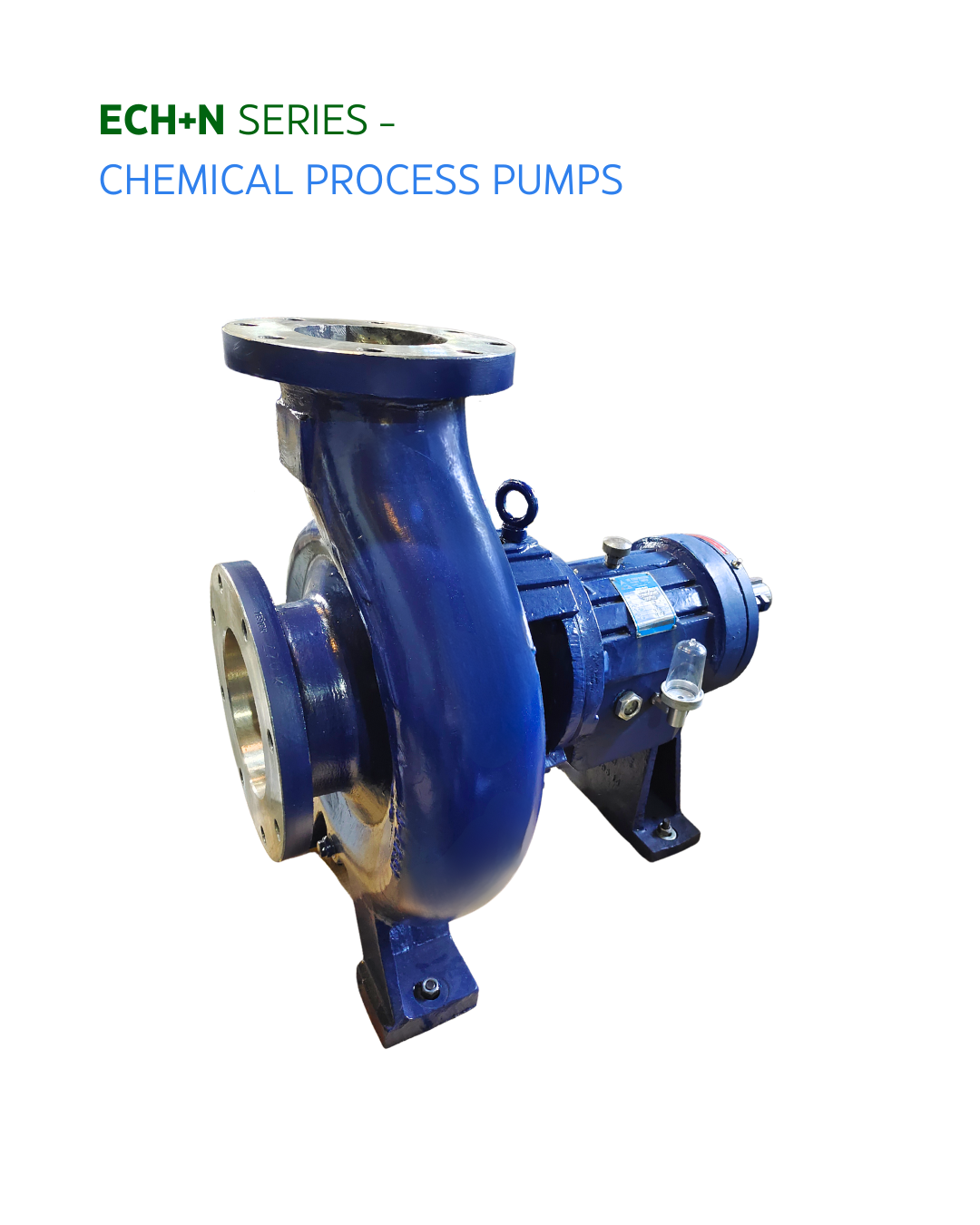

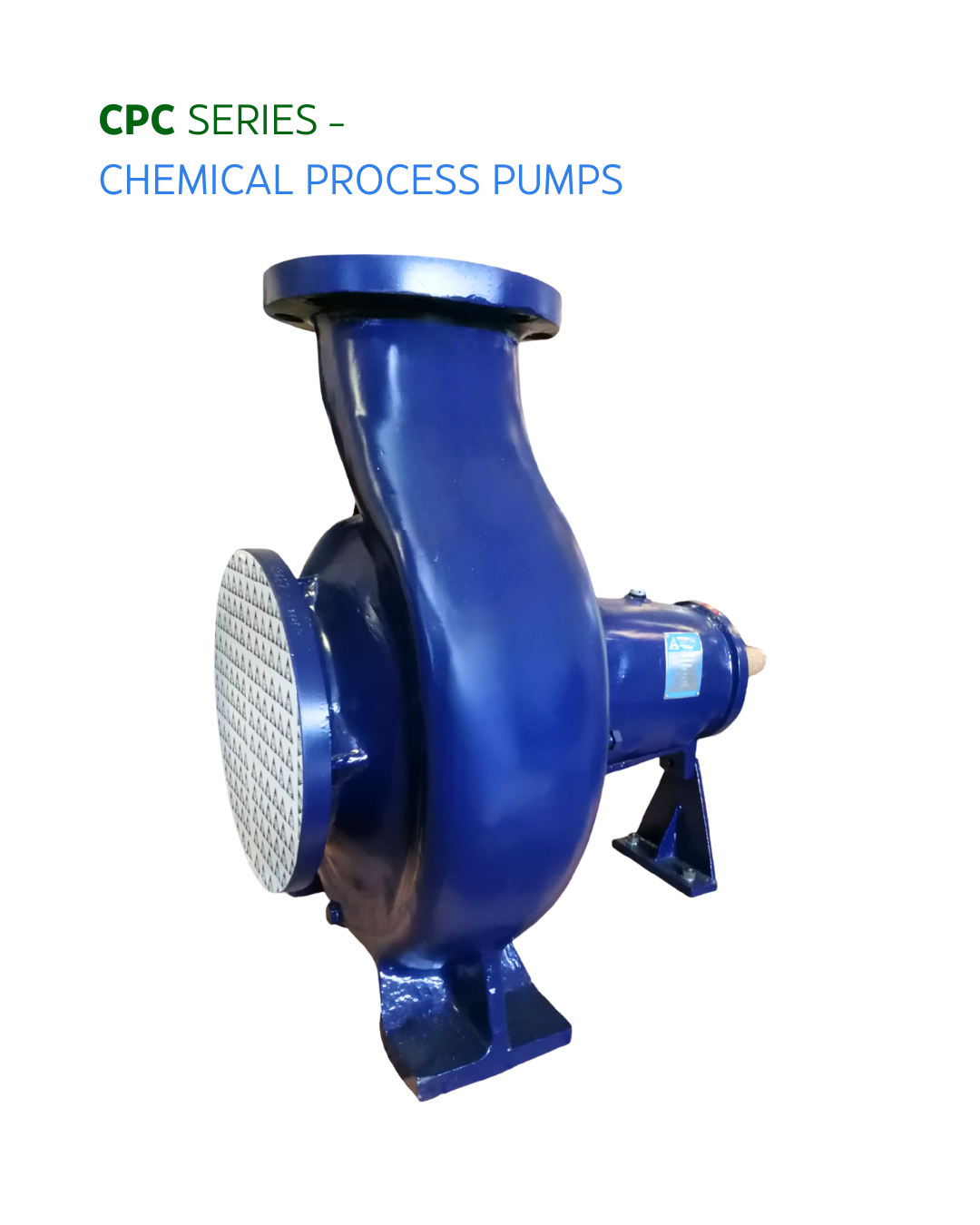

Product Facts :

- Pump Size : DN40mm to 200mm.

- capacity : upto 650m3/hr.

- Head : upto 80m

Features:

Confirming To ANSI B 73.1 | Open Impeller Design | End Suction/ Top centre Line Discharge | Gland Packed / Mechanical Sealed | Simple External Adjustment For Impeller Wear.

Applications:

Handles All Chemical Process Requirements | Acids, Alkalies, Corrosive Slurries | Suitable for all liquids with / without solids | Green Liquor, Black Liquor, Caustic Slurry, Lime – mud slurry, Extraction, Alkalies, Acids, NAOH, China Clay, Fitrate, Hypo, Spent Wash, Starch Etc. in Pulp, Paper Mills.

Product Facts :

- Pump Size : DN200mm to 450mm.

- capacity : upto 3000m3/hr.

- Head : upto 40m

Features:

Horizontal, Single Stage | End Suction & Discharge Branch Tangentially Upwards/ Top Horizontal | Open Impeller Design.

Applications:

Clean, Turbid Or Slightly Contaminated Liquids | Medium & Low Heads in Water Works & Sewage Works | Irrigation & Drainage | Dewatering & Pumping Sea Water | Spray Pond / Injection Water Applications In Sugar Mills | Pulp Transfer / Centric Cleaner in Pulp & Paper Mills.

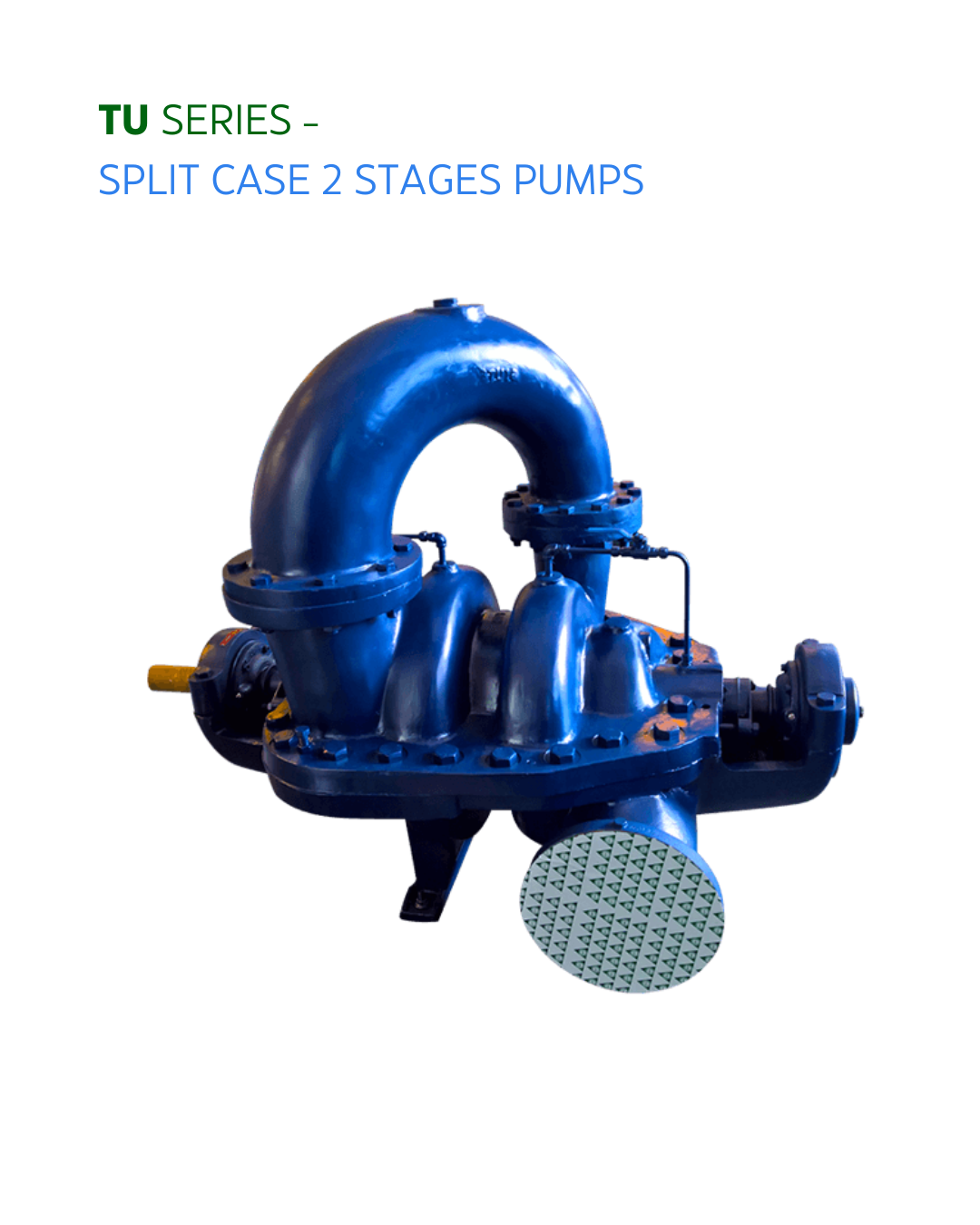

Product Facts :

- Pump Size : DN80mm to 200mm.

- capacity : upto 450m3/hr.

- Head : upto 120m

Features:

Axial Split 2 Stages | High Reliability | Vibration Free | Horizontal Inlet And Outlet | Closed Impeller Design.

Applications:

Water, Fire Fighting | Stock Feed, Stock Circulation, Centri – Cleaner Application In Pulp & Paper Mills | Storm Water, Irrigation | Industries Transfer Works.

Product Facts :

- Pump Size : DN50mm to 700mm.

- capacity : upto 4000m3/hr.

- Head : upto 140m

Features:

Axial Split, Single Stage | Double Suction, Radial Impeller High Reliability & Vibration Free Performance | Gland Packed / Mechanical Sealed | Reverse Rotation Available | Staggered Vane Impeller For Fan pumps to minimize pulsation.

Applications:

Fan Pump, Stock Feed, Stock Circulation, Centric Cleaner Application in Pulp & Paper Mills | Storm Water, Irrigation | Industries Transfer Works | Water , Fire Fighting.

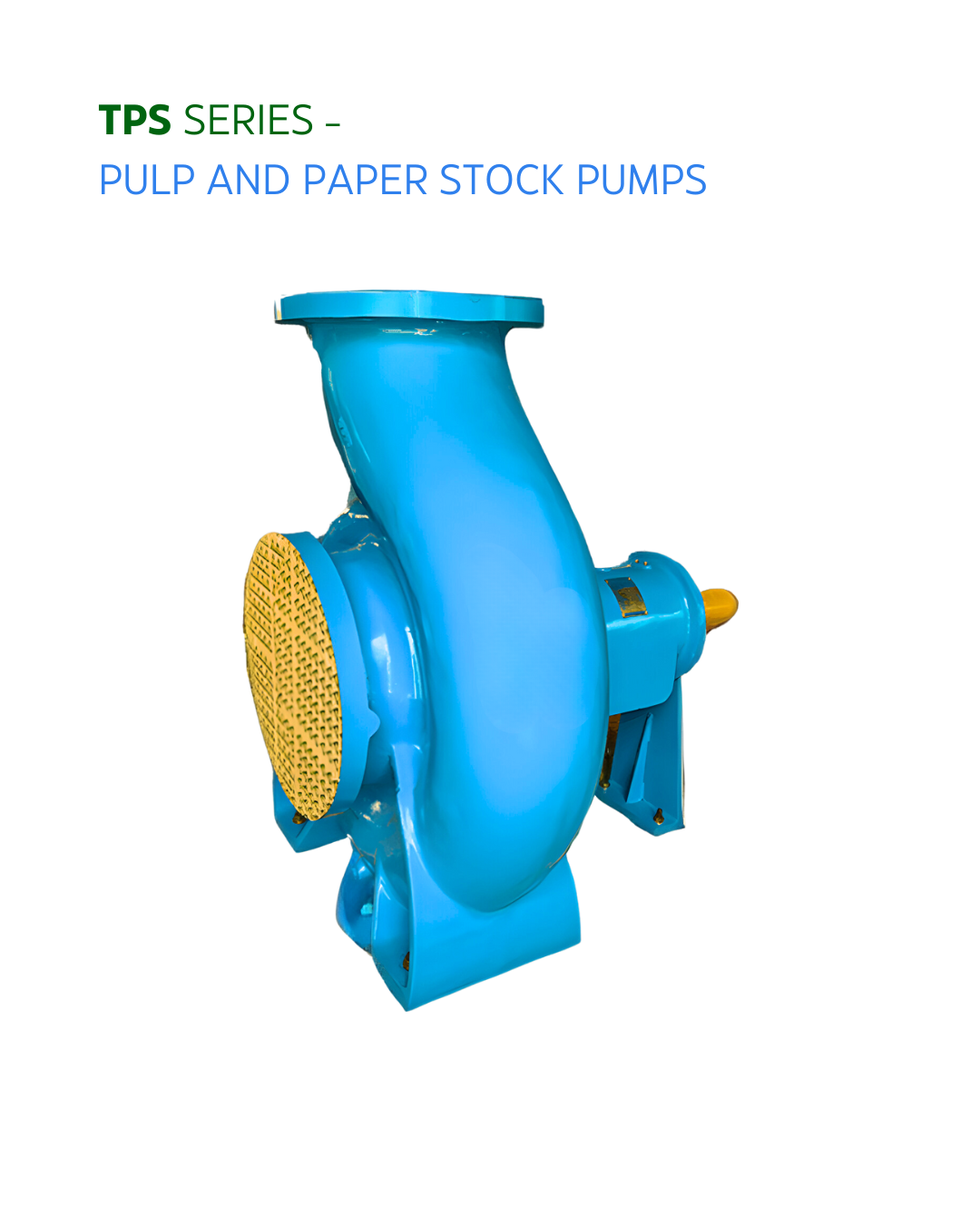

Product Facts :

- Pump Size : DN32mm to 350mm.

- capacity : upto 2250m3/hr.

- Head : upto 80m

Features:

Heavy Duty Design | Confirming To Din 24256 | Open Impeller With Renewable Front Wear Plate | Closed Impeller With Wear Ring | Simple External Adjustment For Impellar Wear | Gland Packed /Mechanical Seal.

Applications:

Handling Pulp & Paper Stocks Upto 7 % Consistency | All Liquor Applications In Pulp & Paper Industries | Suitable For High Capacity Requirements Of Acids , Alkaline, Corrosive Slurries Etc,. | Suitable For Heavily Contaminated Liquids, Raw Sewage, Sludge.

Product Facts :

- Pump Size : DN32mm to 400mm.

- capacity : upto 2500m3/hr.

- Head : upto 80m

Features:

According To Din 24256 Std | Open Impellers With Renewable Front Wear Plate And Closed Impellers With Wear – Ring | Simple External Adjustment For Impellar Wear From Suction Side | Gland Packed / Mechanical Seal / Dynamic Seal.

Applications:

Handling Pulp & Paper Stocks Upto 8 % Consistency | All Liquor Applications In Pulp & Paper Industries | Suitable For High Capacity Requirements Of Acids , Alkaline, Corrosive Slurries Etc,. | Suitable For Heavily Contaminated Liquids, Raw Sewage & Sludge.

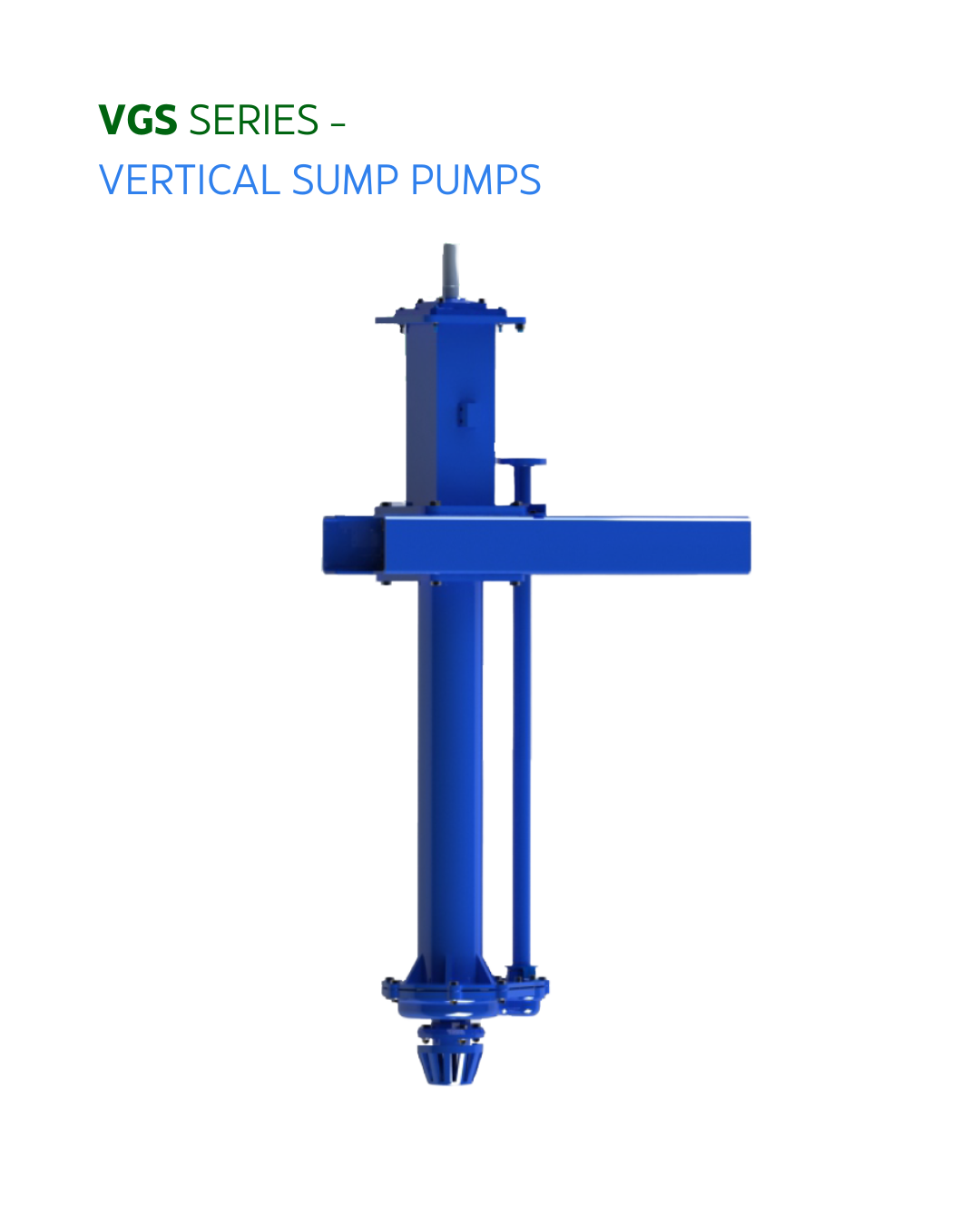

Product Facts :

- Pump Size : DN25mm to 300mm.

- capacity : upto 900m3/hr.

- Head : upto 120m

Features:

Vertical Suspended With Open / Closed Impellers | With Intermediate Bush Bearing Support | Simple Mounting & Self Priming | Up To 10m Submersion Depth | Simple, Fast, External Impeller Adjustments.

Applications:

Suitable Where Space Economy Matters | Suitable For Acids, Alkalies & Slurries in Basic Metal Industries | Waste Water , Sludge Handling In Pulp & Paper Industries.

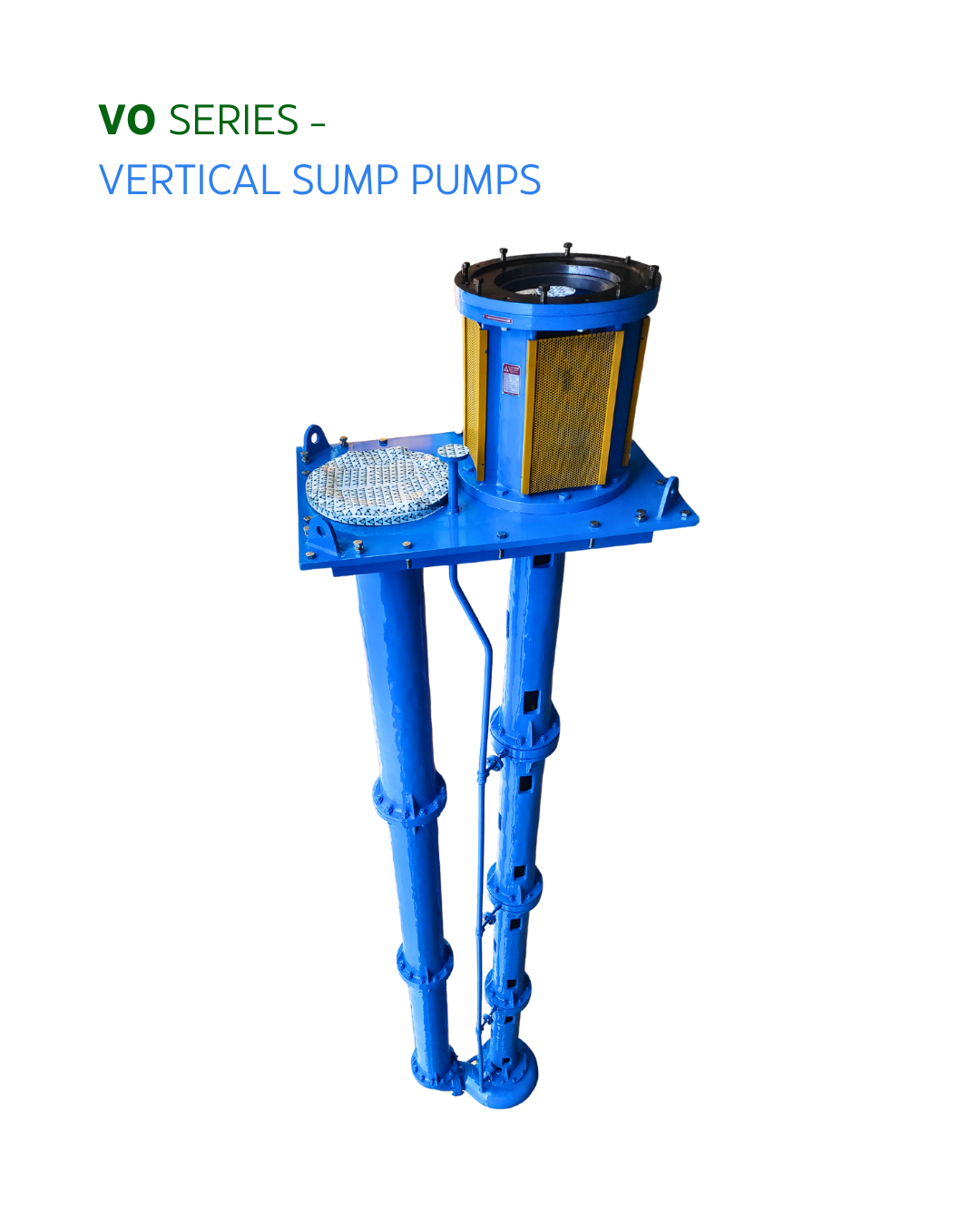

Product Facts :

- Pump Size : DN40mm to 200mm.

- capacity : upto 800m3/hr.

- Head : upto 50m

Features:

Vertical Suspended |Single Shaft Design | No Intermediate Bush Bearing Support | Simple Mounting & Self Priming | Upto 2 mts Submersion Depth | Can Be Extended Further With Suction Spool | Agitator (Optional) | Suction Spool / Strainer.

Applications:

Ash Slurries | Sand Mixtures | Mining & Mineral Processing | Bottom Ash Slurries | Bauxite And Red Mud Slurries.

Product Facts :

- Pump Size : DN25mm to 200mm.

- capacity : upto 400m3/hr.

- Head : upto 50m

Features:

Vertical Suspended |Single Shaft Design | No Intermediate Bush Bearing Support | Simple Mounting & Self Priming | Upto 2 mts Submersion Depth | Can Be Extended Further With Suction Spool.

Applications:

Suitable Where Space Economy Matters | Suitable For Acids, Alkalies & Slurries in All Industries | suitable for Waste Water , Sludge Handling In Pulp & Paper Industries.

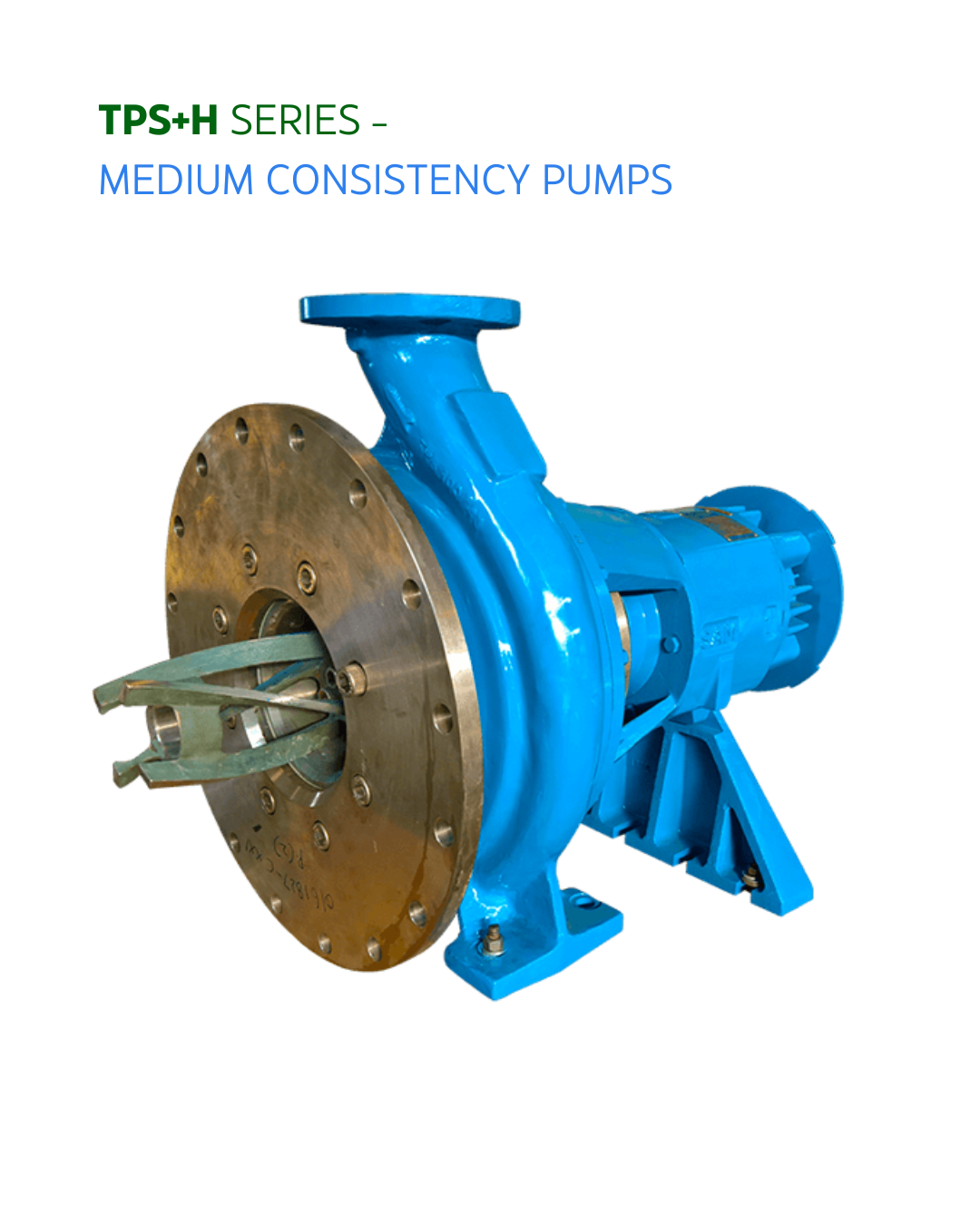

Product Facts :

- Pump Size : DN80mm to 200mm.

- capacity : upto 500m3/hr.

- Head : upto 140m

Features:

Centrifugal & Single Stage | Open Impeller with fluidizer End Suction & Top/Horizontal Discharge | Sturdy & Vibration Free Casing Mounting To the Base Frame.

Applications:

Reliable Pumping of Pulk Stock From 8% To 12% Consistency Supplied Along With Vacuum Pump – in – Built / External Mounted.

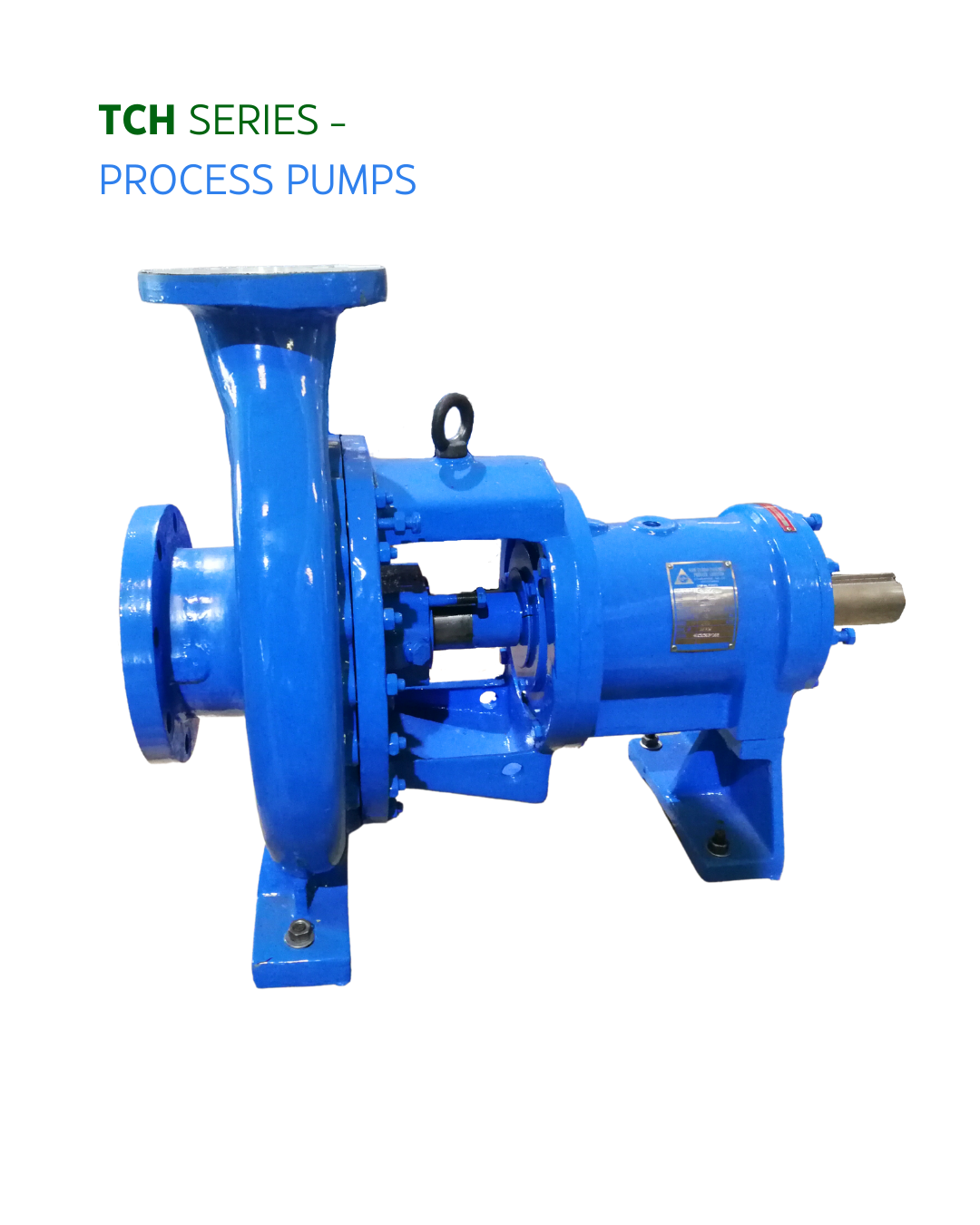

Product Facts :

- Pump Size : DN30mm to 200mm.

- capacity : upto 750m3/hr.

- Head : upto 150m

Features:

Confirming To Din 24256/ ISO2858 | Back Pull Out Design Engineered To API 610 – 6th Edition | Only 4 Bearing Beds To Cover 32 Models | Closed Impeller | Gland Packed / Mechanical Seal.

Applications:

Process, Petrochemicals, Refineries, Fertilizers, Papers, Sugar | Handling Corrosive Acids, Alkalies | Hydrocarbons, Oils| Clarified Water, Back Water, White Water, De-inking Water, Soft Water, Centri Cleaner Application In Pulp & Paper Mills.

Product Facts :

- Pump Size : DN40mm to 100mm.

- capacity : upto 400m3/hr.

- Head : upto 70m

Features:

For Abrasive, Large Particle & Medium Density Slurry | No Need For Any Shaft seal And Sealing Water | No Submerged Bush Bearings | Standard Selection Of Practical Shaft Lengths.

Applications:

Mining & Mineral Processing, Power Plants, Mines And Coal Preparation System.

Product Facts :

- Pump Size : DN40mm to 125mm.

- capacity : upto 350m3/hr.

- Head : upto 45m

Features:

Non-Clogging Operation, Fully Free Vortex Design | Any Solid That Enters Pumps Will Pass Thro’ Discharge | Minimum Particle Degradation | Fluid Does Not Pass Through Impeller, Solids Leave in Single Rotation.

Applications:

For Any Liquid Having Big Particles (Up To 75 mm) | For Sludge, Pulp, Ossein, Slurry Applications.

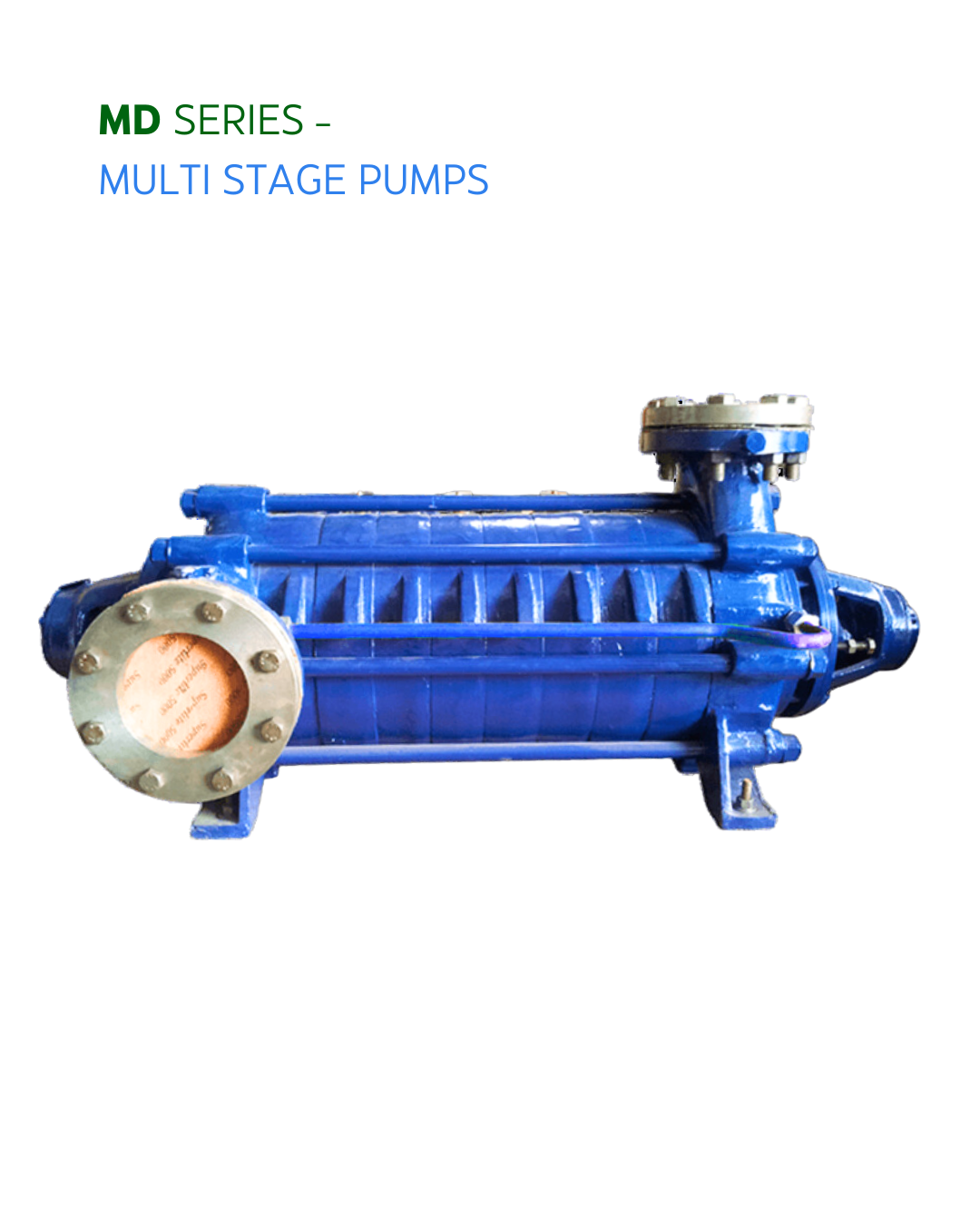

Product Facts :

- Pump Size : DN40mm to 150mm.

- capacity : upto 350m3/hr.

- Head : upto 600m

Features:

Multi Stage With Single Suction Closed Impeller | Axial Thrust Compensated By Balancing Drum/Disc.

Applications:

Main & Auxiliary Condensate Extraction | General Water & Fire – Fighting Systems | Mine Dewatering & Descaling | High Pressure Application In Pulp & Paper Mills.

Product Facts :

- Pump Size : DN25mm to 200mm.

- capacity : upto 700m3/hr.

- Head : upto 180m

Features:

Confirming To ANSI B 73.1 | Open Impeller Design | End Suction / Top Centre Line Discharge | Only 3 Bearing Frames To Cover 32 Models | Gland Packed / Mechanical Sealed | Simple External Adjustment For Impeller Wear.

Applications:

Handles All Chemical Process Requirements | Acids, Alkalies, Corrosive Slurries | Suitable For All Liquids With / Without Solids | Green Liquor, Black Liquor, Caustic Slurry, lime – mud Slurry, Extraction, Alkalies, Acids, NAOH, China Clay, Fitrate, Hypo, Spent Wash, Stark Etc In Pulp, Paper Mills & Basic Metal Industries.

Product Facts :

- Pump Size : DN65mm to 100mm.

- capacity : upto 300m3/hr.

- Head : upto 30m

Features:

Horizontal, Non-Clog | Single Stage | Back Pull Out, High Efficiency Volute, Providing Smooth Unobstructed Flow.

Applications:

For Handling Solids In Suspension | Sludges | Pulpy Materials, Sewage Or Waste With Soft Solids in Suspension, Viscous liquids or liquids carrying fibrous materials.

Product Facts :

- Pump Size : DN80mm.

- capacity : upto 100m3/hr.

- Head : upto 25m

Features:

Centrifugal, Single Stage | Wide Open, Closed, Non Clog Impeller | End Suction, Top Discharge.

Applications:

Pumping Sponge Balls Without Damage For Boiler Tube Cleaning | For All Non Clog Application Liquids Having Foreign Matters.

Product Facts :

- Pump Size : DN25mm to 250mm.

- capacity : upto 1000m3/hr.

- Head : upto 300m

Features:

Confirming To API 610 7th Edition | Centre – line Mounting | Heavy Duty Shaft & Bearings To Withstand High Pressure & Temperature | Double Voulte to minimize Radial Thrust – Above 3 Discharge | Renewable Impeller & Casing Wear Ring.

Applications:

Process Industries & Transfer Systems | Refineries, Oil & Gas Fields, On/off – Shore | Petro Chemicals | Heat Carrier System Boiler Cleaning.

Product Facts :

- Pump Size : DN150 – 760mm.

- capacity : upto 6000m3/hr.

- Head : upto 8m

Features:

Efficiency the innovative technology used in the propeller design makes it capable of realizing its maximum potential in specific flow rates and elevation | The propeller pump is Environmental Friendly. It produces maximum output with minimum Noise and Vibration.

Applications:

Transfering Acids and Alkaline in Fertilizer/ Chemical Plants | Pumping Water | Cooling Ponds | Tanks/Rivers/Oceans Raw Water Intake | Dewatering | Strom Water Removal Flood Control | Urban & Rural Municipal Water | Government Industrial | Irrigation.

Product Facts :

- Pump Size : DN32mm to 200mm.

- capacity : upto 550m3/hr.

- Head : upto 100m

Features:

Confirming To Din 24255 | Back Pull Out Design | Gland Packed / Mechanical Sealed | Closed Impeller Design | Only 3 Bearing Frames To Cover 30 Models.

Applications:

General Water Supply in Agriculture & Industries | Fire Fighting | Booster Service | Clarified Water , Back Water, White Water, De – Inking Water, Soft Water, Centri Cleaner Etc., in Pulp & Paper Mills